Tablets have been popularized as an easy and convenient way to consume medicine or vitamins. With the right ingredients and a bit of know-how, anyone can make their own tablets at home. This beginner’s guide will take you through making your own LFA tablet in no time!

What is an LFA Tablet?

An LFA tablet is a type of tablet made with low-friction atomization (LFA) technology. It was developed by scientists at Rutgers University in the 1980s to improve the manufacturing process for pharmaceutical products. The resulting tablets are much smaller than traditional ones, allowing them to dissolve quickly and evenly when taken orally. Additionally, they are more resistant to damage from moisture or heat due to their smooth surfaces. For these reasons, LFAs are commonly used for over-the-counter medications and dietary supplements like vitamins and minerals.

Choosing Your Ingredients

When selecting ingredients for your LFA tablet, it’s important that you choose the best quality available. Make sure you research each ingredient thoroughly before purchasing it to ensure you’re getting what you need. You should also consider any potential allergies or sensitivities when selecting ingredients as well as any potential interactions with other medications or supplements that may already be part of your daily routine.

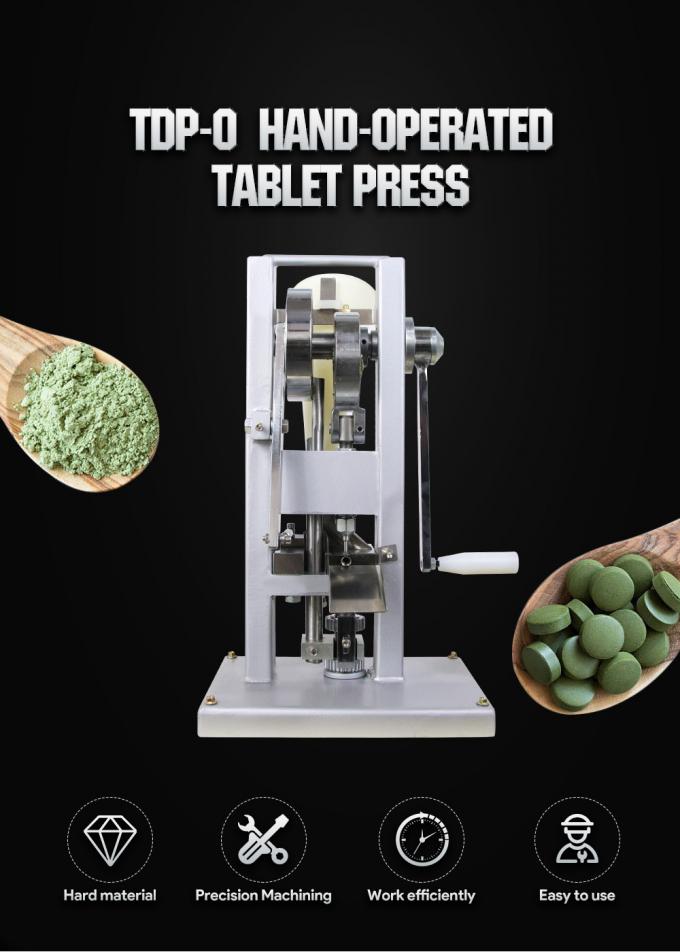

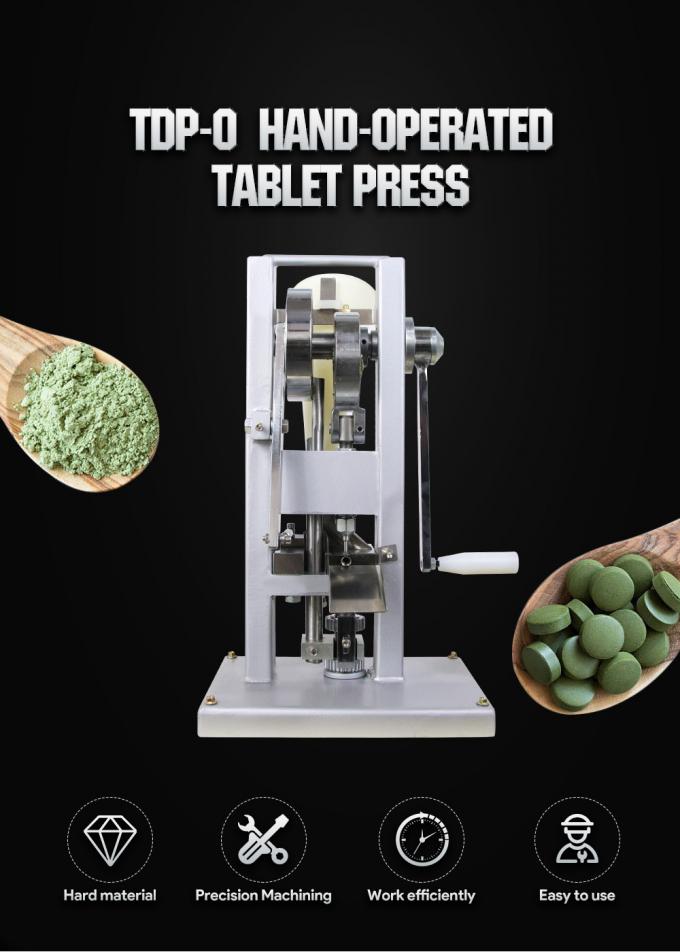

Equipment Needed

Making your own tablets requires some basic equipment including a mixing bowl, measuring spoons/cups, mortar & pestle (or similar grinding device), pill press machine, dies/punches (optional), glove box (optional) and a tablet coating machine (optional). Be sure to research each piece of equipment thoroughly so you can find one that works best for your needs and budget.

Preparing Your Ingredients

Once all the necessary materials have been gathered together, it’s time to prepare your ingredients for tableting. Start by weighing out each ingredient individually using either a kitchen scale or measuring spoons/cups, depending on how accurate you need to be. Once everything is weighed out accurately, combine all the ingredients into a mixing bowl and use a mortar & pestle (or similar grinding device) to grind everything together until it forms a fine powder consistency – this is known as “tablet mass” which will form the basis for your tablets once pressed into shape via the pill press machine.

Using A Pill Press Machine

The next step in creating your own tablets is using a pill press machine which uses pressure and heat to compress powdered “tablet mass” into uniform shapes known as pills or tablets. Depending on what type of pill press machine you have available – manual vs automatic – there may be additional steps involved such as setting up dies/punches before starting up the machine itself so be sure to read through all instructions carefully before beginning this process so everything goes smoothly!

Coating Your Tablets

Once pressed into shape via a pill press machine, many people opt to coat their newly formed tablets with an edible coating material such as sugar syrup or wax which helps protect them from damage during storage or transportation while also offering visual appeal if desired. Again depending on what type of coating material is being used there may be additional steps required such as pre-heating certain liquids prior to application; however, most products come with detailed instructions outlining exactly how they should be used so follow those closely!

Final Touches

Finally, once all of these steps have been completed successfully, then it’s time for some final touches! Depending on what type of product is being created, there may be additional steps required, such as labeling individual bottles containing multiple pills/tablets but generally speaking this marks the end of the process! All that remains now is just storing away any unused supplies safely until ready for use again – good luck!